Supplying high current to a superconducting magnet incurs significant conduction losses through current leads. We designed and tested a synchronous rectifying DC current drive with no thermal linkage between room temperature and cryogenic environments. The high-voltage signal is stepped down by an in-vacuum transformer and converted to DC by a cryogenic synchronous rectifier circuit operating at 18 K and maximum current of 300 A. Proper management of the gating sequence significantly reduces the switching loss, thus making it possible to design a cryocooled magnet system rated for 1,000 - 4,000 A capacity that is cooled with a single cryocooler.

Our capabilities

Magnet design

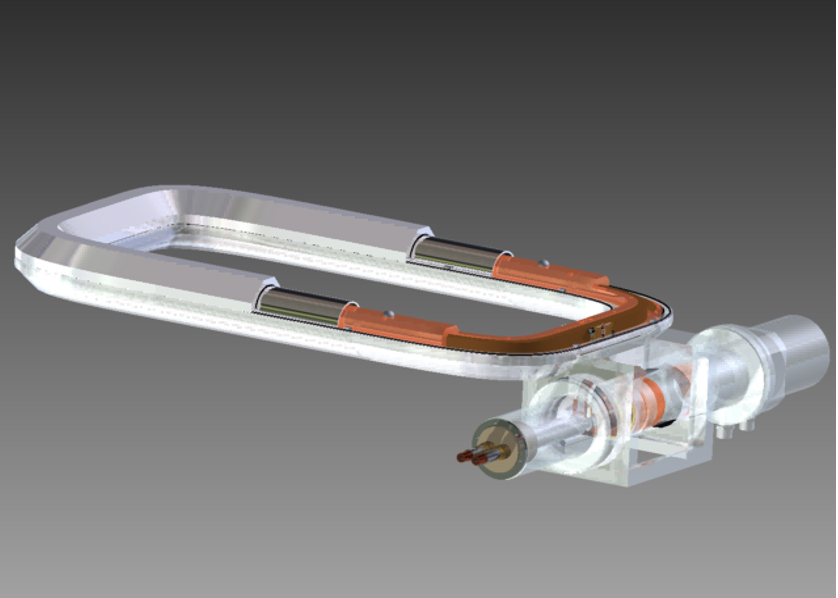

We provide the full cycle of magnet design: vacuum system, mechanical support and cryogenic cooling.

Manufacturing and testing

We design, assemble and test dry-cooled superconducting magnets. Our recent project, funded by U.S. Army, involved manufacturing a coil from 600 m of second-generation wire.

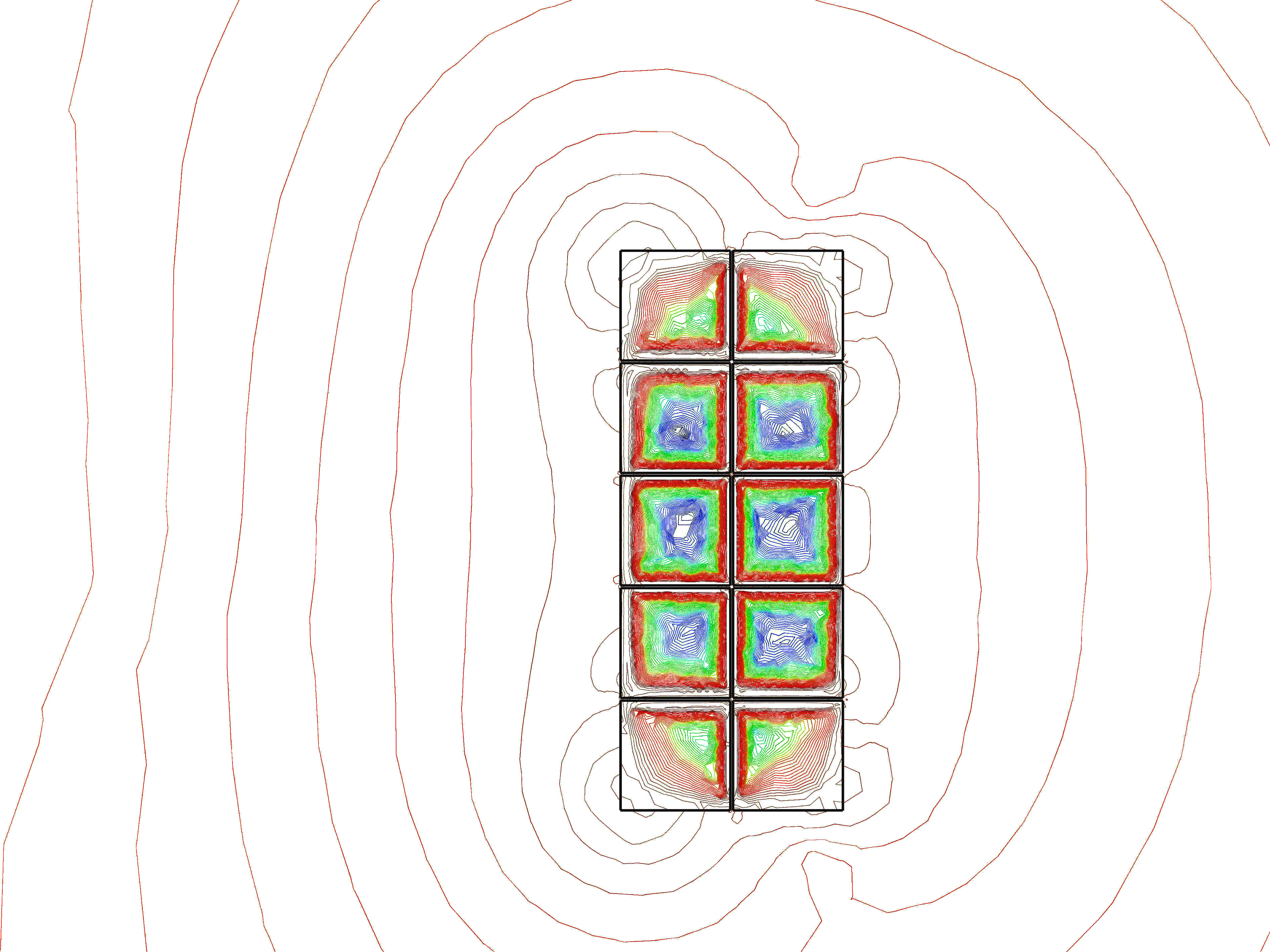

Superconducting magnet modeling

Our capabilities include magnetic, mechanical and thermal finite element analysis. We use the latest numerical models to predict magnetization/coupling losses and the trapped field dynamics in HTS magnets.