ExoCable technology

BTG is developing of a novel symmetric high-temperature superconducting (HTS) YBCO cable, so called ExoCable. The new cable will feature: (i) 1:1 aspect ratio; (ii) a factor of 5 AC loss reduction, up to 20% fill factor and isotropic predictable mechanical strength (the same axial and transverse yield strength, the cleavage strength > 50 MPa). This is achieved by eliminating of the problematic YBCO-buffer interface, which is the weak point of the 2G wire architecture, both electrically and mechanically.

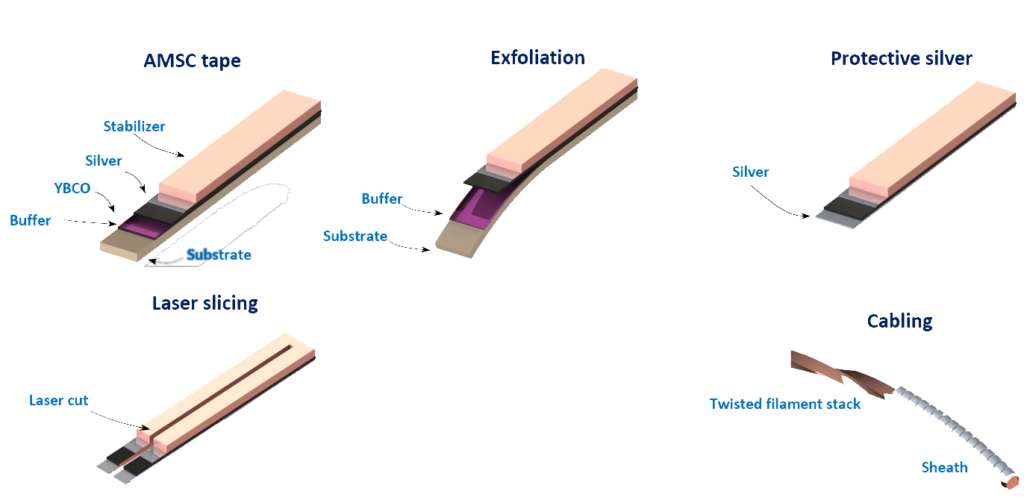

The technology uses the following steps: (i) exfoliation of epitaxial YBCO layer from the substrate, (ii) slicing (laser or mechanical) the filaments and (iii) bundling them into a narrow,1-2 mm wide, as shown in the picture.

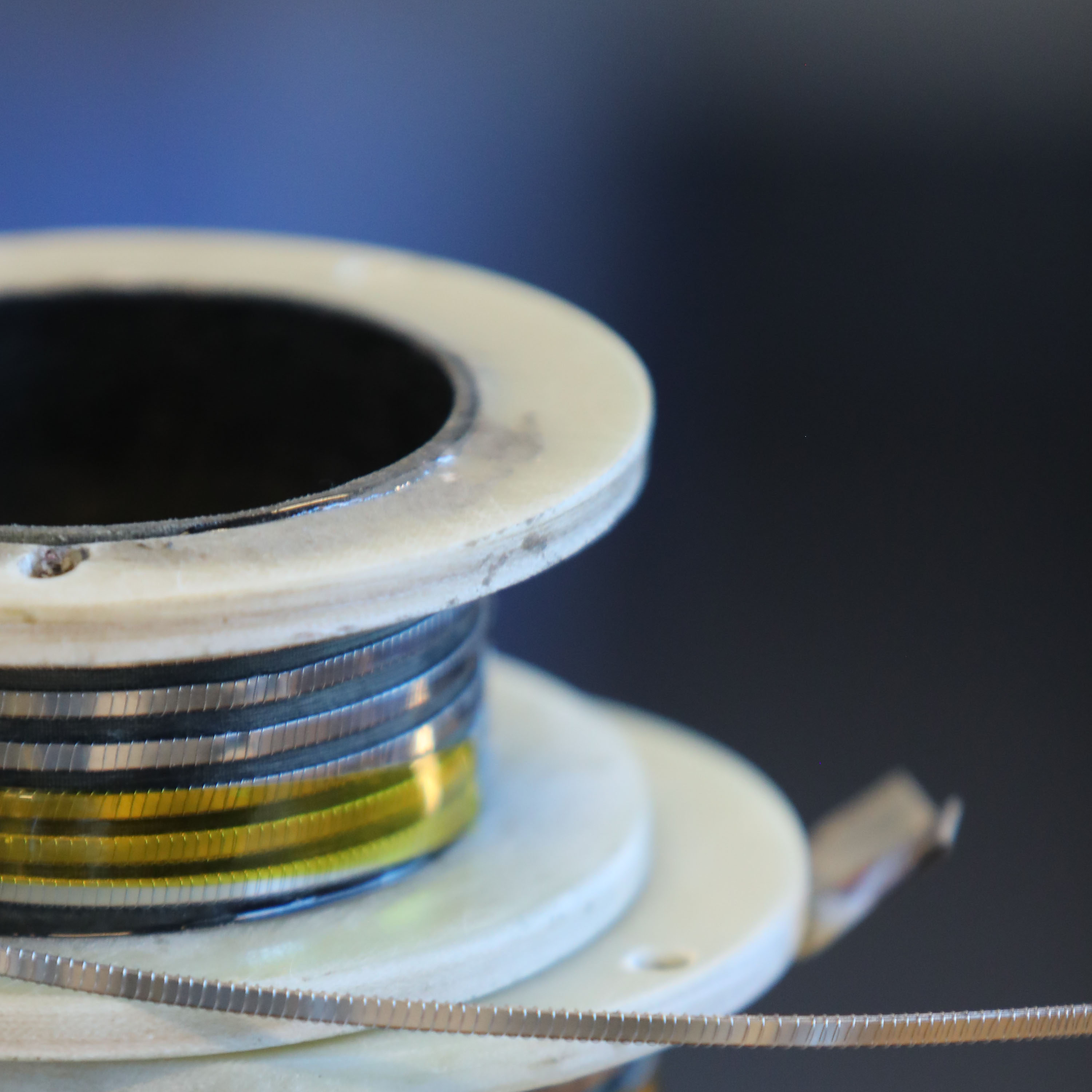

Currently, up to 30 meters of high-quality exfoliated filaments is routinely manufactured. Or laser slicing and cabling systems are capable of handling 100's of meter of filament and cable.

The filaments are bundled into a cable using a custom machine developed by the BTG engineering team.

Advantages of BTG ExoCable technology

Continuous winding

As a traditional wire, the cable can be wound continuously on a coil-form. This eliminates the labor intensive winding and splicing of individual pancake coils.

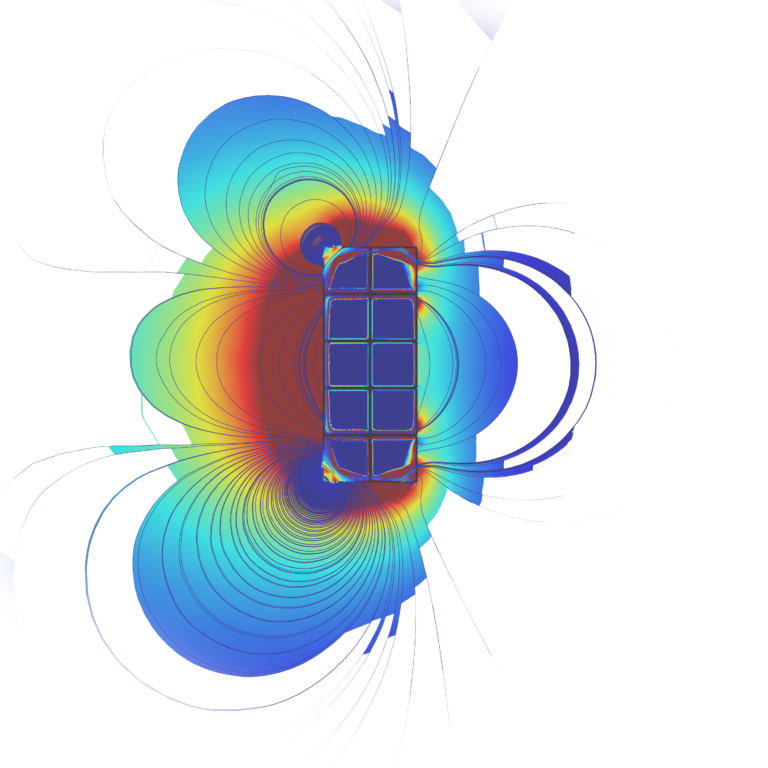

Reduced AC loss

ExoCable has significantly reduced magnetization loss, which allows for fast ramp-up of a magnet. Reduced magnetic moment of the winding contributes to enhanced field quality in the magnet bore.

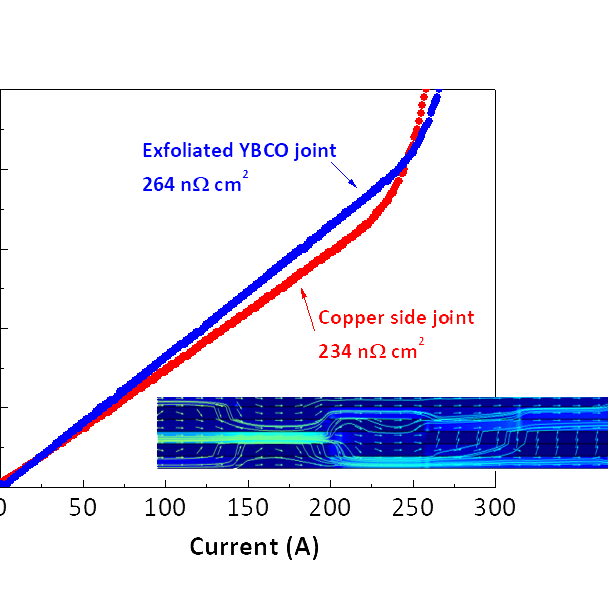

Filament coupling

The exfoliated filaments have low contact resistance on both faces, which allows for an efficient electric coupling and current sharing. The current sharing enhances the quench stability of the cable.

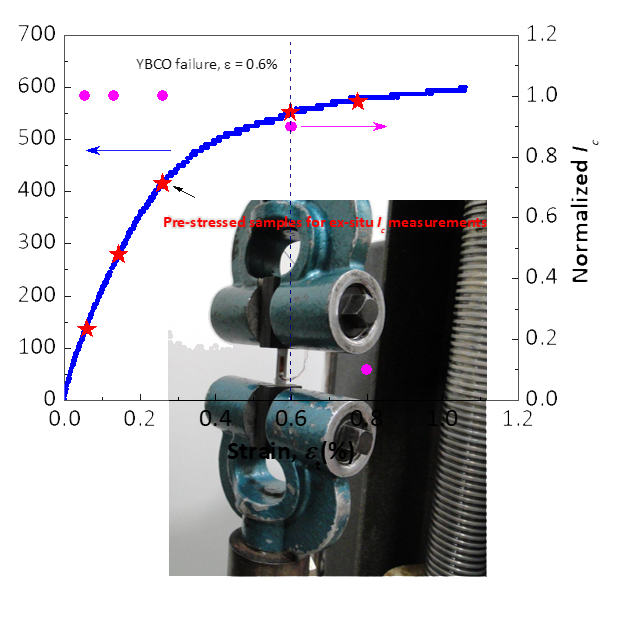

High mechanical strength

The YBCO layer is supported by a stabilizer which can be custom-engineered for the optimum combination of mechanical strength and electrical conductivity.